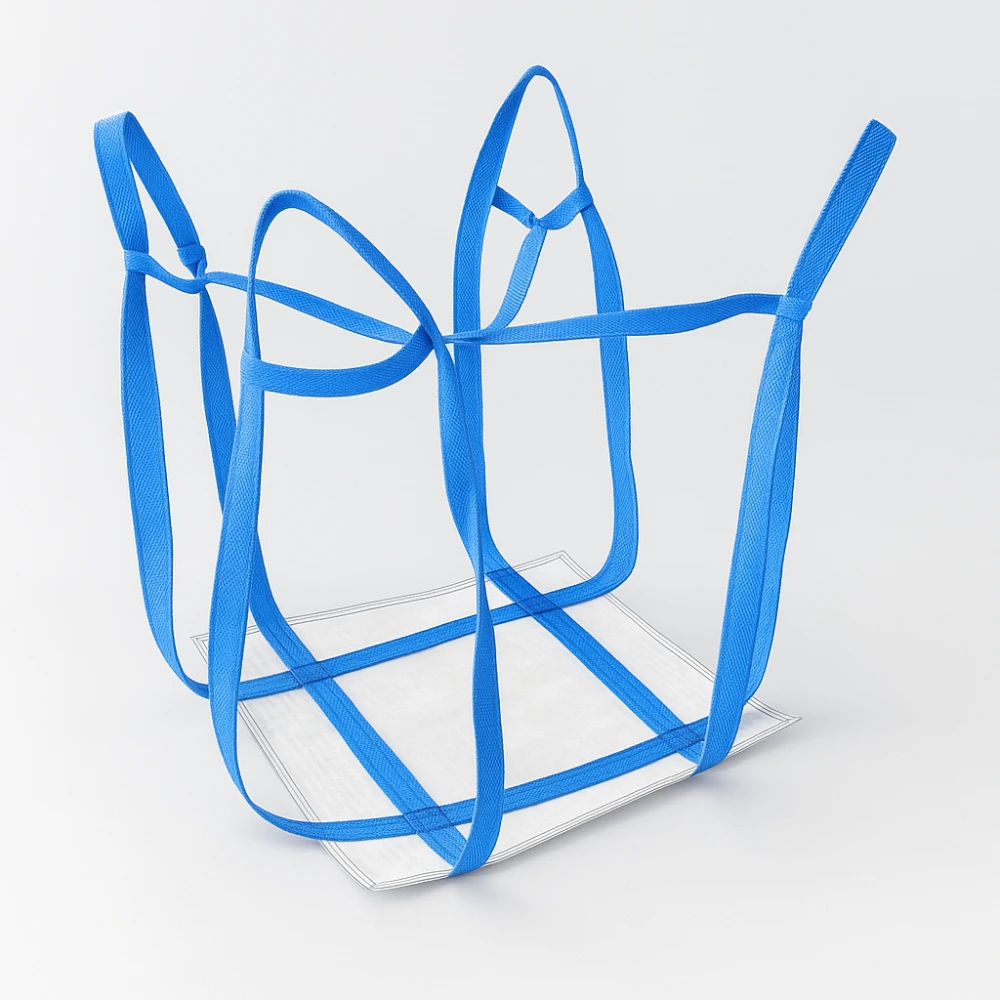

FIBC Jumbo Sling Bags are specialized bulk packaging solutions designed for high-load applications across industrial sectors. These bags are engineered with extended sling-style lifting loops that allow direct forklift handling without requiring pallets. Ideal for transporting up to 2 tons of bulk materials such as minerals, cement, grains, and fertilizers, these bags offer convenience, safety, and durability.

Product Description

Made from premium-grade woven polypropylene, the FIBC Jumbo Sling Bag is a practical choice for operations where efficient lifting, reduced handling, and space-saving logistics are essential. At Prime Terratech Industries Pvt. Ltd., we deliver quality-driven, custom sling bags that comply with international standards for bulk packaging and safety.