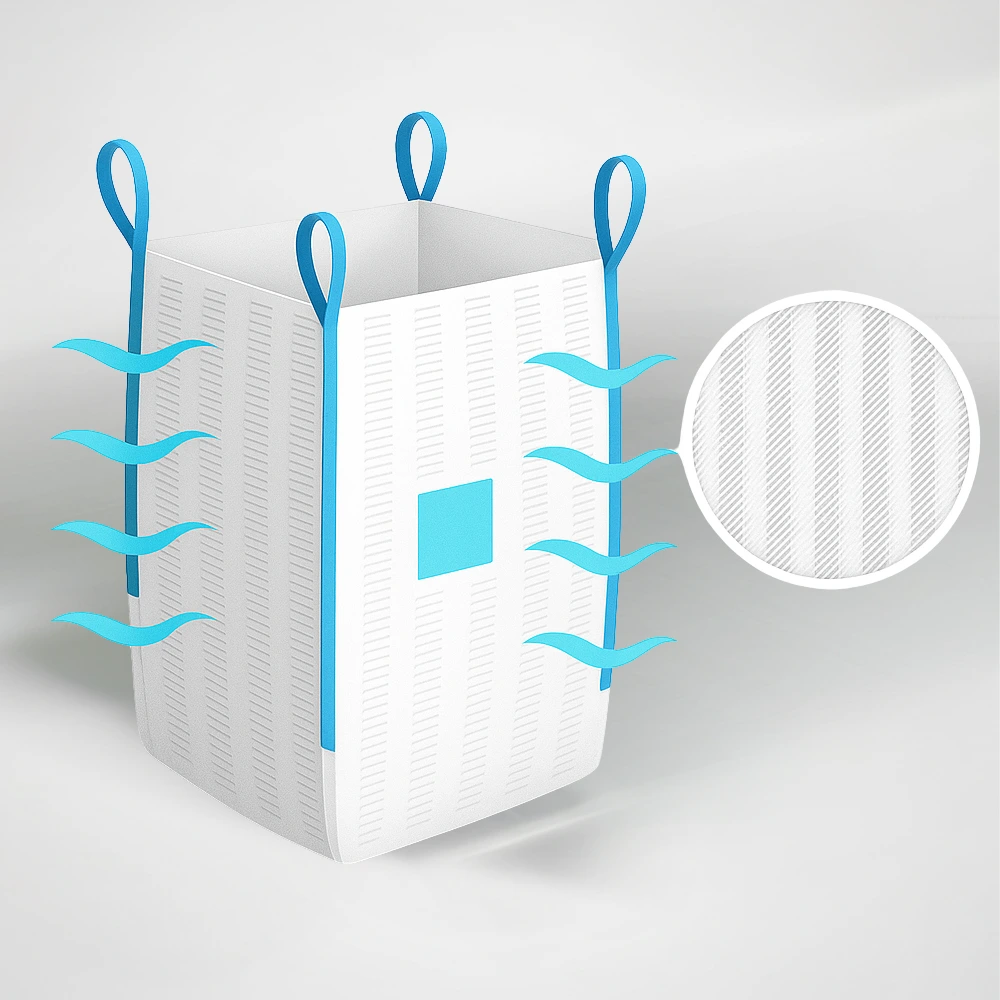

Ventilated Bulk Bags are specially designed FIBC (Flexible Intermediate Bulk Containers) that feature breathable fabric construction, allowing constant airflow through the bag. These bags are primarily used for transporting and storing perishable goods such as firewood, onions, potatoes, garlic, and other agricultural produce that require ventilation to prevent spoilage. The ventilation strips along the fabric help reduce moisture buildup, heat retention, and mold formation. Designed with standard or custom loop configurations, these bags offer high strength, load capacity, and easy handling.

Ventilated FIBC Bags maintain product freshness during extended storage or long-distance transportation. Ideal for agricultural exports and domestic logistics, they ensure consistent product quality from farm to market. These eco-friendly, reusable bags support sustainability and efficient packaging practices for perishable goods industries.