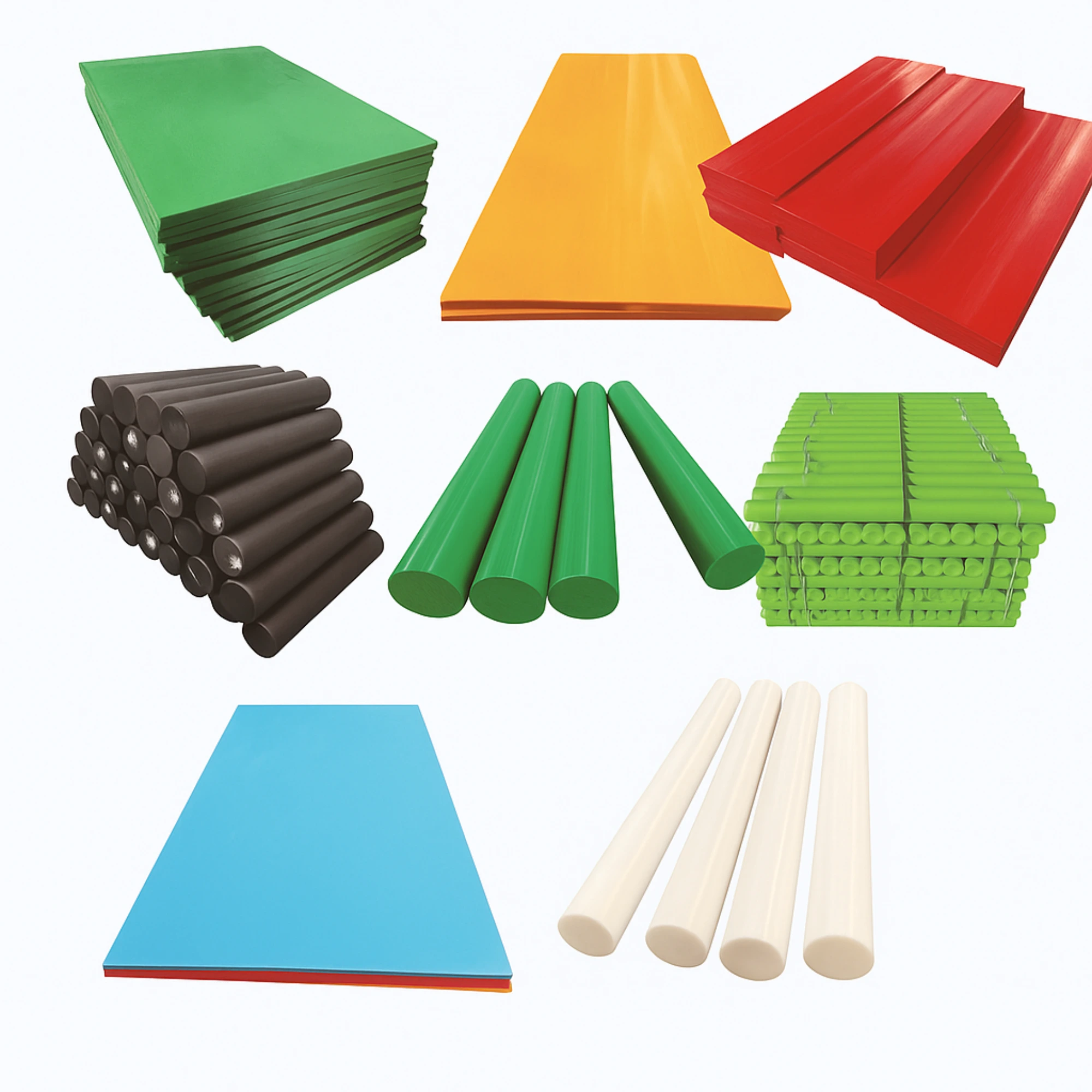

UHMWPE Sheets, Rods & Parts

Prime Terratech’s UHMWPE Sheets and Rods are engineered for industries that demand extreme wear resistance, low friction, and high impact strength. Manufactured in a variety of grades, sizes, and vibrant colors, these sheets are perfect for applications such as conveyor liners, chute liners, food-grade cutting boards, and chemical-resistant components. Their self-lubricating surface minimizes maintenance, reduces noise, and outperforms traditional materials like steel or rubber.

UHMWPE CNC Machined Parts

For precision-critical projects, our CNC-machined UHMWPE parts deliver exceptional accuracy and repeatability. Supported by 50+ CNC engraving machines, milling centers, and advanced tooling, we can create intricate shapes and tight tolerances that meet the exact needs of sectors like packaging machinery, marine engineering, food processing, and mining equipment. Each component is machined to provide smooth finishing, reliable performance, and extended service life.

UHMWPE Customized Parts

When standard products are not enough, Prime Terratech excels in custom-engineered UHMWPE solutions. Our design and fabrication team works closely with clients to produce unique components such as Rolled Sheets, Round Plates, Shafts, Wear Plates, Bearings, Pipe Supports, Pipe Rollers, and Cushion Blocks. Whether it’s a one-off prototype or high-volume production, we provide tailor-made UHMW plastic products that combine strength, flexibility, and long-term durability.